At SSMI, we adopt global leading practices to reduce and minimize the environmental impacts of our operations. Climate change poses one of the greatest challenges of our time, yet it also presents significant economic opportunities. At SSMI, sustainability is woven into the fabric of our business strategy. Our approach to sustainable development is meticulous, focusing on equitable growth that safeguards the environment, nurtures social commitments, and drives economic progress. We have made substantial strides toward building a greener future, emphasizing low carbon emissions and better environmental protection through effective management of pollution, waste, water, and energy. Our goal is to significantly reduce our carbon footprint while promoting responsible practices throughout our operations.

Ensuring sustainable development is a key business responsibility at SSMI and specific resources have been dedicated across businesses towards this purpose. Expected outcomes are clearly defined at the beginning of a financial year and documented in Aspect Documents and are being reviewed on a periodic basis.We at SSMI, have identified key environmental aspects like energy, water, waste, pollution control and biodiversity. We have developed a year rolling road-map for each aspect.

Sustainability has been embedded in SSMI's business strategy to shoulder their economic, environmental and social responsibility. We have made substantial strides toward building a greener future, emphasizing on following initiatives while building a sustainable approach

(Power & Fuel saving)

C02 emission energy

electrical to thermal energy

minimizing extraction by way of

recycled inputs

conservation

through circularity

renewable energy

engagement

commitments

Disclosure of response

to climate change and GYG

emissions performance

Ecolabel & Green product certification

for SSMl's products

'Automotive Steel Product manufactured by Sanyo Steel Manufacturing

India Pvt Limited ("SSMt&) at Khopoli. Maharashtra meets the requirements of

GreenPro Ecolabel and qualifies as Green

- The GreenPro ecolabel, recognizes the highest standards

of environmental sustainability and product performance

in manufacturing - The GreenPro ecolabel signifies that SSMl's products are

manufactured with due care to their environmental impact

throughout their lifecycle, including raw material sourcing,

production processes, energy consumption, and

end-of-life management - SSMI has a plan to conduct LCA (Life Cycle Assessment) of

all categories of products to evaluate the C02-e emission

during the manufacturing of the product - Environmental

Product Declaration (EPD)

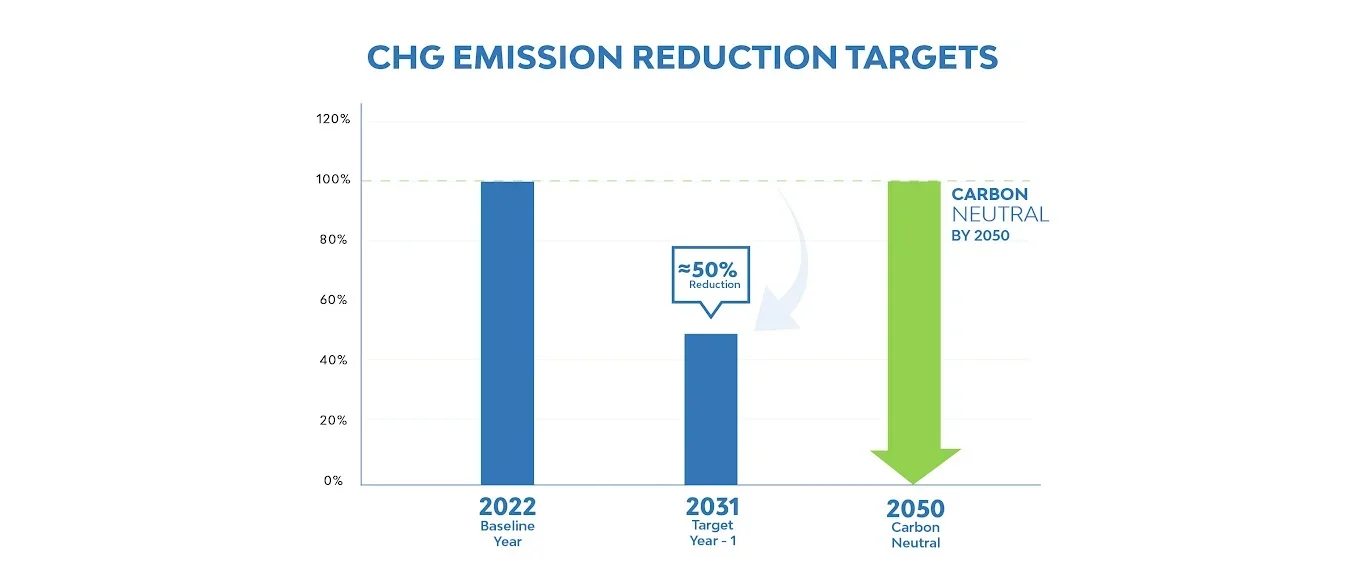

C02 Emission Reduction Targets

SSMI has approved SBTi targets to reduce its Scope-I, Scope-2 and Scope-3 emission:

SSMI has committed to reducing Scope 1&2 emissions per tonne of steel produced 50% by 2031, against a 2022 baseline. And, also

committed to reduce scope-3 emission by 20% by 2031 against a 2022 baseline Earlier SBTi target has been set and approved based

on 2DS SDA(Sectorial Decarbonization Approach), SSMI is in the process of revising the SBTi targets to align with latest criteria of

1.5DS a Net Zero - SAD (Sectorial Decarbonization Approach).

Measures to achieve C02 emission

reduction targets

Reduction in Specific Energy consumption (Thermal as well as Electrical) through various energy conservation measures & adaptation of new technology Development of manufacturing technology to improve energy efficiency..

Substitution of electrical energy to thermal energy by using Natural gas by 2030 and further conversion to green hydrogen by 2050.

2 heat treatment furnaces are already installed.

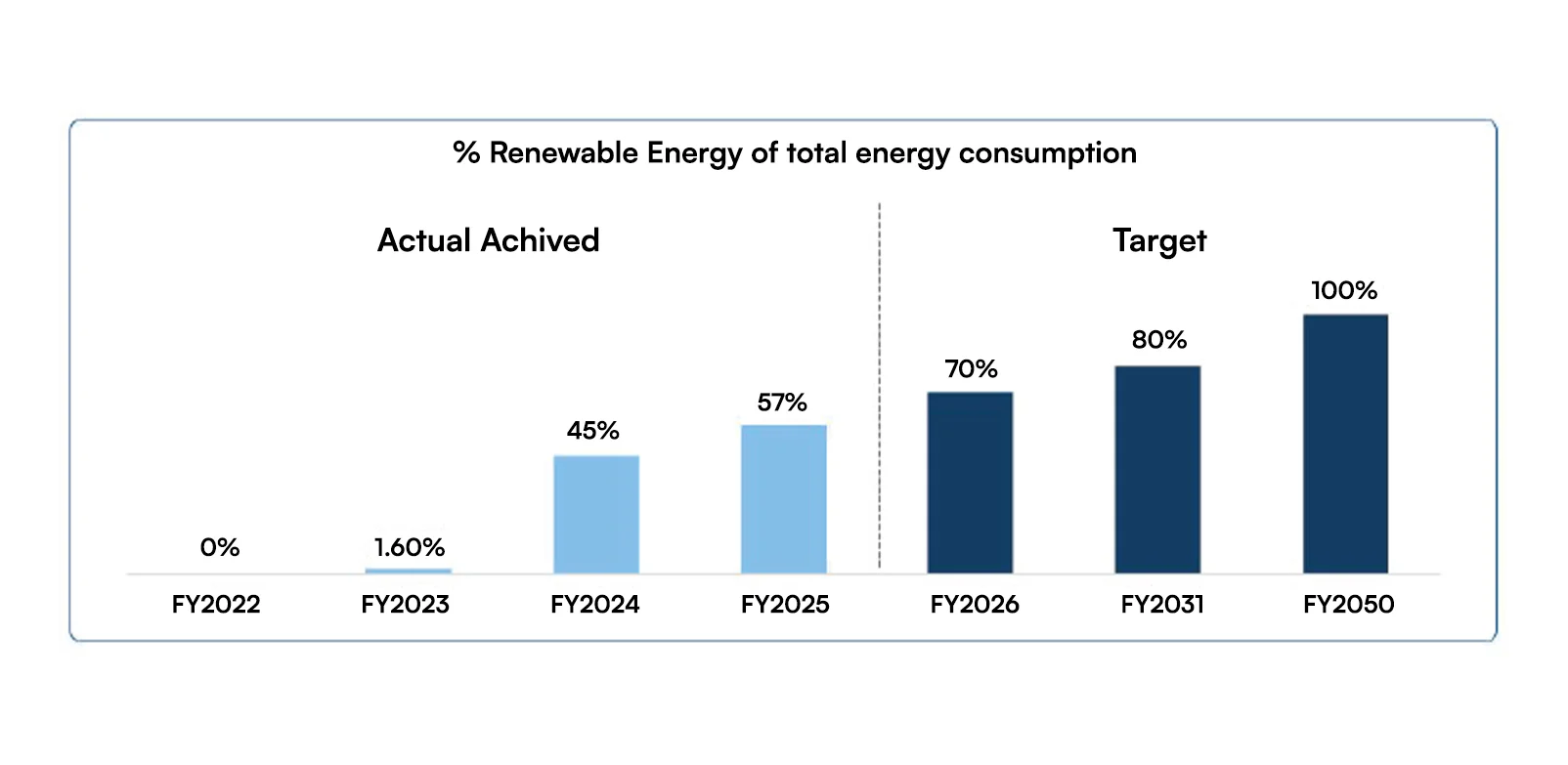

Maximize uses of Energy from Renewable Energy Source such as carbon emission free electricity (Electricity from Wind / Solar) /Low carbon emission fuel (Natural Gas) / Carbon emission Free fuel (Green Hydrogen)

- Fuel Substitution from Oil to Natural Gas by 2025 - 90 % completed.

- Fuel Substitution from Natural Gas to Renewable Source - Such as green Hydrogen / Biomass / alternate renewable source of energy for re-heating furnaces by 2050.

Purchase of Carbon credit / Carbon capture, utilization and storage (CCUS) & conversion of captured CO2 into usable fuel which further can be reused in heating purpose / Tree plantation / Afforestation to offset the CO2 emission.

Major Achievement – FY 24 & FY 25 :

- 8% reduction in Specific Energy Consumption in FY 2024 as compared to FY 23 & 2 % reduction in Specific Energy Consumption in FY 2025 (H1) as compared to FY 2024.

- SSMI Achieves GreenPro Ecolabel for its 'Automotive Steel’ Products

“Automotive Steel Product manufactured by Sanyo Special Steel Manufacturing India Pvt Limited (“SSMI”) at Khopoli, Maharashtra meets the requirements of GreenPro Ecolabel and qualifies as Green Product.”

- 38 % reduction in Scope-1+ Scope-2 GHG emission in FY 2024 as compared to FY 2023 & 30% reduction in FY 2025 (H1) as compared to FY 2024 – All comparison is in Specific Emission (T-CO2 / T of crude steel production). SSMI has been honoured by CDP at a joint event held on June 4 in New Delhi. This was in recognition of SSMI's longstanding commitment to the environment, including receiving the highest rating of "A" in the CDP Supplier Engagement Rating (SER) category for 2023.

- Sanyo Special Steel Manufacturing India Pvt. Ltd. was honoured at the 7th Edition of CII GreenPro Summit 2024 on 16th & 17th October 2024 in New Delhi by The Confederation of Indian Industry (CII). This was in recognition of SSMI's GreenPro Ecolabelling certification for Automotive Steel Product. SSMI has been awarded with plaque from CII-Green Products & Services Council for its GreenPro Ecolabelled Automotive Steel Product.

- SSMI Signs Power Purchase Agreement for Renewable Power (Solar Power) with Tata Power Renewable Energy Limited by investing Rs.130 Mn on CPP concept in the project to get renewable energy on long term basis – contract is for 25 years.

- Sanyo Special Steel Manufacturing India Pvt. Ltd. was honoured at 3rd Supplier meet by CIE, India at Pune. This was in recognition of SSMI’S ESG initiatives.

Responsible Manufacturing

With increasing pressure on resources, we are constantly seeking ways to make smarter use of resources.

We want to best manage our favourable and unfavourable impact on the environment and society, and

address all sustainability-related challenges.

Steel & Sustainability

Knowing that the steel sector is perfectly positioned to contribute to a circular economy, we intend to highlight the role of responsible steel and share best practices with our peers and other associated organizations.

Our Environmental Footprint

80-85% of our input for production is scrap, ensuring that we save even before we use- One of our efforts is to increase recycled input. However, we use the Electric Arc Furnace (EAF) that makes our core operations energy-intensive, necessitating substantial effort in this area. We have begun a series of initiatives to ensure that our products are less energy-intensive and use less water in the manufacturing process. One of our key enablers in product responsibility is to conduct ife Cycle Assessment (LCA) of products, thereby adopting appropriate migratory steps using less inputs and less harmful materials to manufacture our products, increasing our use of recycled input material including scrap, recycling wastes, etc. to approach zero landfill.

Accreditation and review

Environment management systems are key to increase our operational efficiency by helping us monitor our environmental performance- From being the first Indian steel manufacturer to be ISO certified to promoting excellence internally through various assessment we are committed to quality and our production facilities are well certified, with EMS ISO 14001, OHSAS ISO 18001 and EnMS •SO 50001. We set annual benchmarks on identified focus areas and review our overall environmental performance against previously set targets, We also define initiatives and measures pertaining to each of our goals.

Cost of energy is significant in overall costs of steel production, it is becoming

increasingly important to reduce our electricity and fuel consumption. Use of

EAF (Electric Arc Furnace) for manufacturing makes us significantly

energy-dependent. We aspire to become the benchmark in the class by

methods improvement and through best technology adoption. Over the years

we have reduced specific fuel consumption through methods of improvement

as well as technology change. In addition to the above, we have invested in

fuel substitution from Oil to Natural Gas for further reduction of GHG emission.

We have adopted a road map to reduce our environmental footprint with

identified key projects to achieve in specific electricity consumption. Also, there

is a target to reduce the specific fuel consumption. We have invested in

different energy efficiency projects over a period of time. Few years back

we introduced Oxy-Fuel technology in our furnaces which improves heat transfer

in combustion. This technology not only helps us to reduce our oil

consumption but also to reduce our pollution load in the process.

We take efficiency measures towards steel recyclability and technology which has helped in emission reduction. The use of energy in producing steel results in Efficiency of carbon dioxide. sulphur oxides, nitrogen oxides and dust. Efficiency measures. steel recyclability and technology has helped in emission reduction.

Reduction of GHG emissions is highly relevant to us and addressing scope 1,2 and 3 emissions while reducing our dependence on fossil fuels forms a part of our eco-efficiency focused efforts. Our goal is to ensure high air and water quality by minimizing our pollution levels and looking to new solutions and process improvements while continually monitoring our emissions.

Implementation of oxyfuel technology in our reheating furnaces led to a drop of over 50% in our pollution load- We have revamped all our chimneys/stacks to improve air filtration„Fuel substitution from Oil to Natural Gas has resulted in further reduction of GHG emission of the organization,

& afforestation

SSMI has an aspiration to switch over its 80% of the total energy consumption to renewable energy. An attempt in the same direction is that the unit has already made a long term contract with TP Alpha Limited (A subsidiary of Tata Power Renewable Energy Limited) to get solar power for 25 years on Captive Arrangement by the investment in TP Alpha Limited. The unit has started getting solar power from TP Alpha Limited,, which is further renewable energy contribution for its operation. A start by setting up solar power panels to take care of the lighting load of its administrative building. We are also receiving electricity from other wind & solar power stations which will further reduce our carbon footprint.At SSMI, tree plantation drives are elementary to our biodiversity management measures.

Water is used for cooling, processing operations and there is equal emphasis on both availability and quality

We are dependent on a single source of water - the Patalganga River to make the water available to us. We collaborate with local stakeholders such as the irrigation department and key suppliers to understand possible implications on raw materials with respect to water availability and quality, and are aligned with the National Water Policy since 2011.

Following a Water Audit by third party MACE and MITCON to understand water use pattern, leakages and wastes, we built an internal check dam for rainwater harvesting and ground water recharge. We reuse grey water from our Sewage Treatment Plant for industrial use and gardening, while using rain water for industrial top up, and have set targets to reduce industrial lift and consumption volumes. The newly commissioned RCC water pond eliminates the ground seepage losses. We are working towards Recycling & Reuse of water. We have adopted water efficiency improvement, water recycling and water reuse practices at every operation. Plant is Zero Effluent Discharge as the water system is in closed loop and again re-used for industrial and other purposes. Underground pipeline from source of water intake to plant has been changed with new overhead pipeline, eliminating the losses / pipeline leakage.

Water scarcity can put increased

pressure of natural resource availability

on the steel industry and it is important

that our company increases efficiency,

manages water resources and invests In

new technologies to conserve and

recover lost water,

We continually work with our employees, vendors, customers to increase our production efficiency, ensure that we reuse or recycle at every opportunity to minimize waste generation, and dispose our waste in a responsible manner. We also counsel our communities to use water and energy efficiently while reducing emissions, and provide support to handle waste effectively. We encourage newer resource efficiency measures at our sustainability review every quarter while examining industry best practices for the forthcoming quarters.

To improve our resource intensity, we are measuring our resource consumption, recycled input material levels, and natural resource input. We have been able to reduce rejections, increase recycled input material, reduce surface defects, and improve end-to-end yield across multiple products.

Approximately 80-85% of our input is recycled steel scrap today, and we have set our sights on an 80% recycled input in the future. Using scrap enables us to save on conserving significant raw materials and divert valuable material from going to landfills. Steel production typically generates by-products or residues such as scales, slags, sludge and dust. We either treat or reuse these during production, or sell to other industries. For instance, we recycle a portion of refractory bricks every month.

Recycling not only keeps materials from being sent to landfills, but also enables 100% usage of scrap in steel production making steel the most recycled industrial material globally. When the full life cycle of steel products is taken into account, steel enables a sustainable society, through a circular economy. By-products or residues from steel are inevitable and include scales, slags, sludge and dust. If not reused, they may be sold to others.

As part of our waste management measures, we are aiming at reducing our landfill rate, reusing our manufacturing

output, responsible e-Waste management,

and moving towards zero hazardous

waste.

We are sending refractories bricks and papers to

gain full utilization. All our hazardous waste material generated are sent to authorized recyclers and are stored in secured landfills wherever applicable. All our electronic waste is recycled through an authorized recycler. In order to engage employees more actively in our zero waste goal, we undertake Waste to Wealth theme-based months for capacity building and receive employee suggestions. Our goal is a Zero Waste to Landfill system, where all solid and hazardous wastes will be recycled or reused.

We are working on a small unit for separation of metal from the slag. This will enable us to send this slag for road construction cement manufacturing and other gainful utilizations.

Exploring and researching on the use of Fume Extraction System (FES) dust for circularity in pig iron industry industries.

As global steel production increases, the volume

of by-products, residues, and overall waste going

to landfills will grow. There 's a need for stronger

REED to ensure maximum reduction or reuse of

waste generated by companies.

Steel production typically generates

by-products or residues such as scales, slags,

sludge and dust. We either treat or reuse

these during production, or sell to other

industries. For instance, we recycle a portion

of refractories bricks every month.

To support the biodiversity in the area of our operation,

we ensure that every new process is assessed for its

likely environmental and biodiversity-related impact.

It is important that any change in production or other

operations does not adversely impact air or water

quality, or result in habitat loss. We have successfully

planted more than 10,000 trees per year for the last 3

consecutive years. We also have conducted a detailed

biodiversity study to understand nature biodiversity

aspects within the area of operation.

We are creating a biodiversity park in our

premises and undertaking species

identification studies as part of our

restoration effort.

In an effort to extend the benefits of our

Environmental Life Cycle Impact Assessment and

have an integrated view of our sustainability, we

engaged with Trucost for our Natural Capital

Valuation in 2014 where we evaluated our products

at the Khopoli site Putting a monetary value to

environmental impacts such as pollution,

dependency on water use, natural resource

consumption, and applying Natural Capital Valuation

to our product Life Cycle Assessment data will help

drive our sustainability product decision making in

the longer run.