Stakeholder Engagement

and Materiality

Engaging with our stakeholders is key to our company vision and effort. While we aspire to be the

most admired and socially responsible organization, materiality is the prime means to achieve and

monitor this aspect. It is important for us to understand the issues each of our stakeholders care

about, and to communicate our challenges, initiatives, and progress on all of them.

Engaging with our key stakeholders

is important to SSMI and helps drive our

sustainability vision

Materiality Analysis

We engaged over 200 internal and external stakeholders through various mediums to conduct a materiality analysis that helped us identify issues concerning materials in terms of importance and impact. We were guided by several frameworks including the GRI, World Steel Association, Brown Flynn, Stratos, Sustainability, Accountability, Fronesys, IIRC, BSD etc, Depending on whether a specific stakeholder group strongly influenced, or was strongly influenced by, our environmental, social and economic performances, the groups were prioritized and engaged.

We worked based on a multi-phase iterative materiality testing methodology that includes a ranking and prioritization of potential material aspects, mapping on a risk-opportunity matrix, consultations and review. Over a span of two years and 4 phases, we narrowed down from an initial list of 68 to 12 material issues across the ecological, social, financial & human capital dimensions. These are listed below.

GHG Footprint

Efficiency

Management

Prevention

Management

Intensity

Supply Chain

Inputs

Skill

Health. Education and

Employability

Employee Safety

Accountability

The Way Forward

We have piloted e Revalue, a cloud-based analytics to continuous and dynamic materiality scanning regulatory, reputational and stakeholder expectation issues globally and locally including peer activities in a sectoral and cross-sectoral manner. In the future, we look forward to bringing in collaborative materiality analysis in the value chain by extending the current boundary. To further strengthen our value chain, we are engaging our Tier I and Tier II suppliers to create awareness regarding sustainability,

Managing Our

Supply Chain

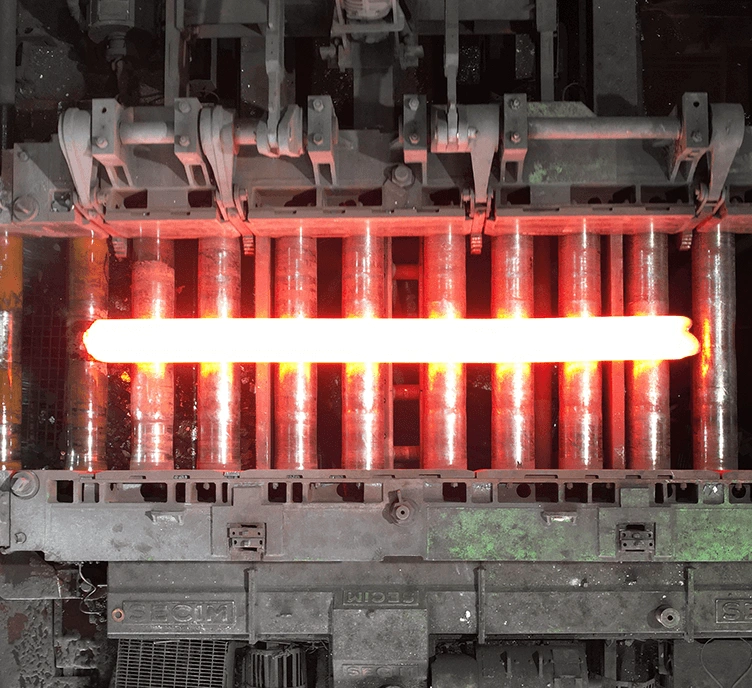

At SSMI, we believe in inclusive growth. As a sustainable steel manufacturer in India, we are committed to sustainably sourcing, producing, and supplying to our customers.

As a policy to engage with our stakeholders, especially our suppliers, we have made them sign and agree to our Supplier's Code of Conduct (COC). This practice has been adopted for all the suppliers added. We expect our suppliers to comply with these requirements as a condition to do business with SSMI. We have a huge bank of suppliers and every year suppliers are shortlisted for the audit based on the share of business or the nature of business.

Once the supplier qualifies for the product sample test and other preliminary enquiry and scrutiny, only then they are considered to be a permanent Once eligible to be taken in as the approved supplier, they are made to sign the Code of Conduct which is a comprehensive document of the working procedures and priorities with SSMI. The Code of Conduct in its broad purview contains "Minimum Standards" & "Qualifying Standards".

Responsible procurement

We have a comprehensive procurement policy that includes sustainable sourcing. We have been discussing responsible procurement with our suppliers as well, preparing them for our procurement policy that will additionally consider sustainability parameters.

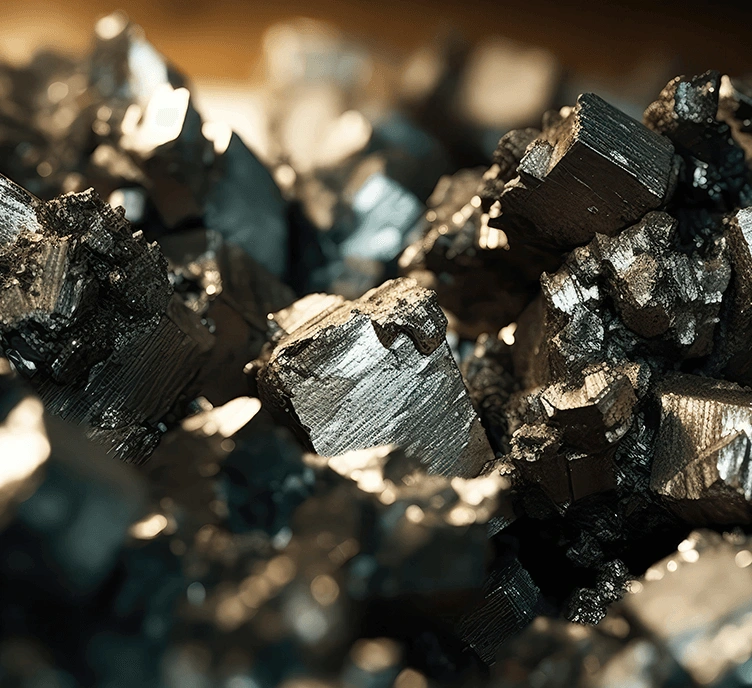

Our input is recycled steel scrap. We have identified specific areas where we need to work more closely with our suppliers to increase our consumption of recycled input material. We desire to increase local sourcing in the coming years.

The aim is to identify the hotspots and improvement opportunities or to manage risks in supply chains. The participation and support allow for identifying the positive impacts and how these can be strengthened, while the risks of negatives can be better managed. In that way, it can be a source of inspiration for product business driver and sustainability.

As a policy to engage with our stakeholders, especially our suppliers,we have made them sign and agree to our Supplier’s Code of Conduct (COC). This practice has been adopted for all the suppliers added. We expect our suppliers to comply with these requirements as a condition to do business with SSMI. We have a huge bank of suppliers and every year suppliers are shortlisted for the audit on the basis of the share of business or the nature of business.

Once the supplier qualifies the product sample test and other preliminary enquiry and scrutiny only then they are considered to be a permanent supplier. Once eligible to be taken in as the approved supplier, they are made to sign the Code of Conduct which is a comprehensive document of the working procedures and priorities with SSMI. The Code of Conduct in its broad purview contains “Minimum Standards” & “Qualifying Standards”.

In case the suppliers are identified of non-compliance over the qualifying standards while signing the contract, they are expected to have targets and action plan for reaching the qualifying standards and in the process we work with our suppliers to help them bridge the gaps and reach the targeted goals.

The supplier’s capacity building on various issues new to them is taken care of, and they are motivated and encouraged through the timely recognitions and awards. The capacity building of the suppliers in the past has been taken up the company along with collaboration with the BSI. In fact the company has its own internal auditors trained on BS8903. The company also has its auditing SAQ’s prepared with the help of BSI.

With a view to extend sustainability across our supply chain, we have been organizing Sustainable Supply Chain Management workshops for our suppliers since the past four years. Tier 1 suppliers with the organized sector and unorganized sector have been engaged on GHG accounting, LCA, corporate governance, etc. We have also been gathering supplier feedback through the Supplier Self-Assessment Questionnaire. Besides supply chain policy, the interaction with the suppliers down all the tiers gradually is in tune with the Vision.

Collaborations

The India GHG Program is a voluntary initiative to standardize the measurement and management of GHG emissions in India. We are a founder member and happy to be associated with the India GHG Program, a joint initiative by WRI India, TERI and Cll.

The objective of GPMDG is to scale-up Indian green energy markets and enable corporate buyers to access reliable & clean energy, diversify their energy portfolios with green power and reduce their impact on climate change while creating new opportunities for renewable energy suppliers and technology providers. We are a member of GPMDG India, a joint initiative by WRI-lndia and Cll

The Alliance for Integrity is a business-driven multi-stakeholder initiative between private sector, civil society, political organizations and international institutions. It aims at promoting clean business practices and fair competition as a means to a stable, secure and responsible business investment climate. SSMI is the advisory partner with Alliance for Integrity.

SSMI is collaborating with Australian Steel Stewardship Council for developing sustainability certification scheme called Responsible steel, designed to provide certification of compliance with nominated sustainability criteria for all sectors of the steel supply chain, and covers the full life cycle of steel.